Unlock the Perfect Finish: Cerakote vs. Powder Coat

Achieving the ultimate finish for your projects is no longer a distant dream; it's within your grasp! Welcome to the thrilling world of coatings, where the battle between Cerakote and powder coat rages on. But wait, there's a twist! In this groundbreaking article, we'll reveal a secret weapon: the power to do both Cerakote and powder coat in your very own ovens. Yes, you read that right! Imagine the endless possibilities and unprecedented convenience of having the flexibility to conquer any project with the perfect coating option. Get ready to unlock the perfect finish as we dive into the epic showdown of Cerakote vs. powder coat, unveiling their unique strengths and highlighting why it's not just encouraged but essential to consider both applications.

Understanding Cerakote and Powder Coat: Exploring Characteristics and Applications

Cerakote, known for its ceramic-based composition, is applied using advanced spraying techniques that guarantee a flawless and uniform coating. This coating offers remarkable durability, protecting surfaces against wear, abrasion, and impact. Additionally, Cerakote serves as a reliable shield against corrosion, making it an ideal choice for applications in challenging environments. What sets Cerakote apart is its extensive range of colors and finishes, such as matte, glossy, metallic, and camouflage. This versatility allows for personalized customization and artistic expression, ensuring a visually stunning and superior finish.

Powder Coat Characteristics and Application

Powder coat is applied through an electrostatic process where dry powder is charged and sprayed onto the substrate. This results in an even and uniform coating. The powder particles adhere to the surface, creating a strong bond. To achieve a durable and attractive finish, the coated object is then cured under heat, allowing the powder to melt, flow, and chemically react. This will eventually form a solid coating.

In terms of durability, powder coat excels by providing high resistance against chipping, scratching, and fading. This makes it very suitable for applications that are exposed to harsh environments or frequent use. Powder coat also demonstrates exceptional versatility. It can be applied to a variety of materials, including metal, wood, plastic, and more. This broadens its range of potential uses.

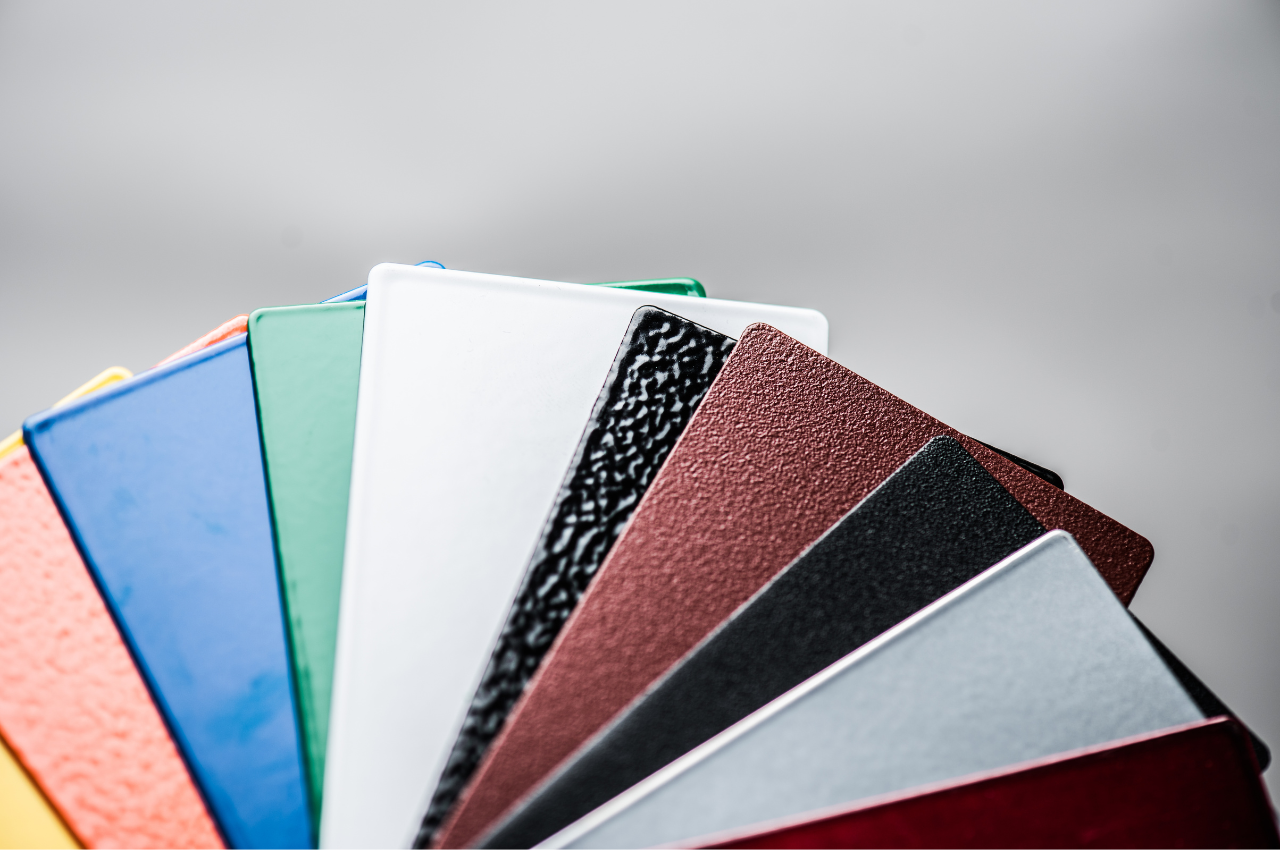

Powder coat also stands out for its visually appealing characteristics. These visual characteristics provide a diverse selection of colors, textures, and finishes to cater to different preferences and needs. Whether you prefer a smooth, textured, metallic, or matte appearance, powder coat provides limitless design possibilities. This versatility makes powder coat the preferred choice for both functional and decorative applications.

Unlock the Perfect Finish: Comparing Cerakote and Powder Coat

To achieve the perfect finish, it's important to notice the similarities and differences between Cerakote and powder coat. Both techniques offer finishes that are durable and long-lasting, but they each have unique characteristics that make them suitable for different purposes. Factors like cost, durability, appearance, and specific usage are crucial in deciding which method to choose.

Cerakote is well-known for its exceptional durability and provides a protective coating that can withstand extreme conditions. It excels in applications where resistance to abrasion, chemicals, and corrosion is required. On the other hand, powder coat offers a wide range of colors and textures, allowing for endless customization possibilities. It is ideal for projects where aesthetic appeal and versatility are important.

Cerakote tends to be slightly more expensive due to its advanced formulation and specialized application process. On the other hand, powder coat is often more cost-effective, making it a popular choice for larger projects or customers on a budget. Cerakote's exceptional toughness ensures long-lasting protection for surfaces that endure wear and tear. Powder coat, while still durable, may be more susceptible to chipping or scratching under heavy use or impact.

When it comes to appearance, Cerakote provides a sleek and smooth finish that enhances the visual appeal of any surface. In contrast, powder coat creates a thicker and textured finish, adding depth and character to various objects. The specific use cases of Cerakote and powder coat should also be taken into account. Cerakote is particularly suitable for firearms, automotive parts, and industrial equipment, where durability and corrosion resistance have a high priority. Powder coat finds its applications in sectors like architecture, furniture, and consumer goods, where customization and aesthetic versatility are highly valued.

The Benefits of Providing Both Applications

Offering both Cerakote and powder coat services provides numerous advantages that can significantly benefit your business and customers. By providing both Cerakote and powder coat services, you gain a competitive edge and position yourself as a comprehensive solution provider. This versatility allows you to meet the diverse preferences and requirements of your customers. Whether they seek the durability and protective qualities of Cerakote or the customization options of powder coat, you can cater to a wider range of needs, ensuring customer satisfaction and loyalty.

Emphasize the Ability to Cater to a Wider Range of Customer Preferences

Every customer has unique aesthetic preferences and functional requirements for their projects. With both Cerakote and powder coat in your service offerings, you can accommodate various styles, colors, and textures. Whether a customer desires a sleek, polished finish or a textured, vibrant look, you can deliver precisely what they envision. This flexibility fosters stronger customer relationships and helps you establish a reputation for meeting diverse demands.

Open Up New Revenue Potential

The decision to expand your services to include both Cerakote and powder coat opens up new revenue potential. By diversifying your offerings, you tap into different markets and attract a broader customer base. This expanded customer reach translates into increased sales opportunities and higher revenue streams for your business. With a comprehensive range of services, you can capture the attention of more customers and secure a competitive position in the industry.

Save Time and Resources

Performing both applications in your ovens offers convenience and operational efficiency. Having the capability to handle both Cerakote and powder coat within your facility saves time and resources. It eliminates the need to outsource or send projects to different locations, streamlining your workflow and reducing turnaround times. This efficiency enhances customer satisfaction and allows you to take on more projects, further maximizing your profits.

By incorporating both Cerakote and powder coat services, you unlock a host of benefits for your business. From catering to diverse customer preferences to expanding revenue potential and optimizing operational efficiency, the advantages are plentiful. Embrace the opportunity to provide a comprehensive finishing solution to your customers and position your business as a go-to destination for top-quality finishes. Visit Lightarmor to learn more and explore how you can leverage these benefits and unlock the full potential of your services.